Reinforced concrete drafting ensures structural integrity and longevity through tailored steel bar placement, advanced modeling software, optimal rebar spacing & size, and critical connection details. Adherence to building codes prevents weaknesses and enhances durability in demanding environments from seismic zones to high-traffic areas.

Concrete reinforcement is a cornerstone of durable structure construction. To ensure longevity and structural integrity, meticulous detailing is essential. This article guides you through the critical aspects of reinforced concrete drafting, focusing on understanding material needs, designing efficient steel bar layouts, optimizing rebar spacing and size, and ensuring robust connection details. By mastering these elements, you’ll create robust, long-lasting structures capable of withstanding time and environmental pressures.

Understanding Concrete Reinforcement Needs

Concrete reinforcement is a critical aspect of ensuring structural durability and longevity, especially in challenging environments. Understanding the specific reinforcement needs of a project is the cornerstone of successful reinforced concrete drafting. Every structure has unique demands based on factors like load capacity, climate conditions, and material properties.

For instance, structures in seismic zones require different reinforcement techniques than those facing severe weather conditions or high traffic loads. Drafters must consider the type of reinforcement—such as steel bars, mesh, or fibres—and their placement to create a robust framework capable of withstanding expected stresses and strains. This involves meticulous planning, incorporating relevant building codes and standards, and often employing advanced modelling software for accurate analysis.

Drafting Effective Steel Bar Layouts

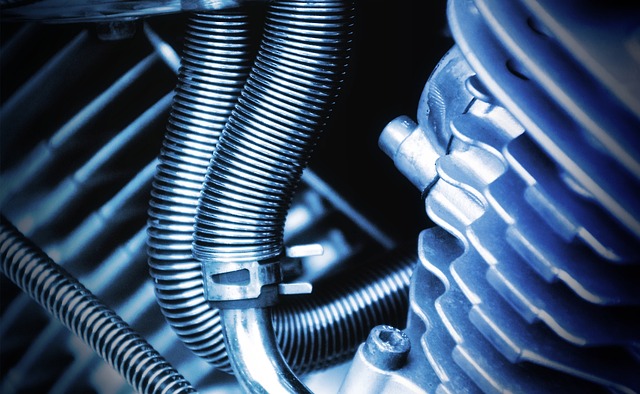

Effective steel bar layouts are crucial in reinforced concrete drafting, as they directly impact the structural integrity and durability of a building. Crafting precise plans involves careful consideration of the structure’s load-bearing requirements, ensuring each steel bar is positioned optimally to reinforce concrete members such as beams, columns, and slabs.

Professional engineers utilize advanced software and mathematical calculations to draft these layouts. They meticulously map out the length, diameter, spacing, and orientation of steel bars, adhering to building codes and standards. This meticulous process not only enhances structural strength but also plays a vital role in preventing cracks, corrosion, and other potential weaknesses, ultimately contributing to the longevity of the constructed structure.

Optimizing Rebar Spacing and Size

Optimizing rebar spacing and size is a critical aspect of reinforced concrete drafting, ensuring structural integrity and durability. Proper detailing involves balancing factors like load capacity, concrete strength, and the potential for crack development. As a rule of thumb, rebar should be placed at intersections and corners to handle concentrated stresses, with spacing determined by span length and load requirements.

In draft plans, it’s essential to consider both diagonal and vertical rebar arrangements to prevent crusting and reduce the risk of concrete degradation. The size of reinforcement bars (rebar) should be proportionate to the structural demands, larger diameters providing more strength but increasing material costs. Engineers often use mathematical models and testing data to fine-tune these dimensions, ensuring structures withstand various loads without compromising longevity.

Ensuring Proper Connection Details

In the realm of reinforced concrete drafting, ensuring proper connection details is paramount for durable structures. These connections, often overlooked yet critical, include bonding between steel bars and concrete, as well as interfaces among various structural elements. Accurate detailing guarantees that the reinforcement acts cohesively with the concrete matrix, enhancing overall structural integrity. Professionals must adhere to established guidelines and standards to achieve these seamless integrations, utilizing appropriate couplers, lap lengths, and mechanical or chemical anchoring methods as required by the project’s design.

Proper connection details not only strengthen the bond between steel and concrete but also mitigate potential failure modes, such as slip, pullout, or bending. Precise drafting involves meticulous planning and precise execution to meet structural requirements and ensure the longevity of built structures. Effective communication among architects, engineers, and construction teams is essential in implementing these critical connection details, ultimately contributing to robust and safe reinforced concrete structures.

Concrete reinforcement is a cornerstone of durable structural design. By understanding the specific needs, drafting effective steel bar layouts, optimizing rebar spacing and size, and ensuring robust connection details, we can create reinforced concrete structures that stand the test of time. These key considerations ensure not only structural integrity but also longevity, making them essential for any construction project aiming for resilience and reliability. Through proper implementation, reinforced concrete drafting becomes a powerful tool to build safe, sturdy, and aesthetically pleasing structures.