Steel structure drafting is a vital skill ensuring accurate assembly and communication in fabrication and manufacturing. Shop drawings, as detailed blueprints, translate design concepts into measurable specs, facilitating precise planning for cuts, welds, and assembly. Integrating these drawings with advanced techniques like laser cutting and robotic welding automates workflows, maintains quality, and enables efficient data exchange, ultimately enhancing overall project success.

In the realm of fabrication and manufacturing, precision is paramount. Accurate shop drawings, rooted in meticulous steel structure drafting, serve as the bedrock for transforming design concepts into tangible reality. This article delves into the critical role of steel structure drafting in ensuring seamless integration throughout the manufacturing process. We explore how precise drawings enhance quality assurance, foster efficiency, and ultimately deliver exceptional structural integrity.

Understanding Steel Structure Drafting Importance

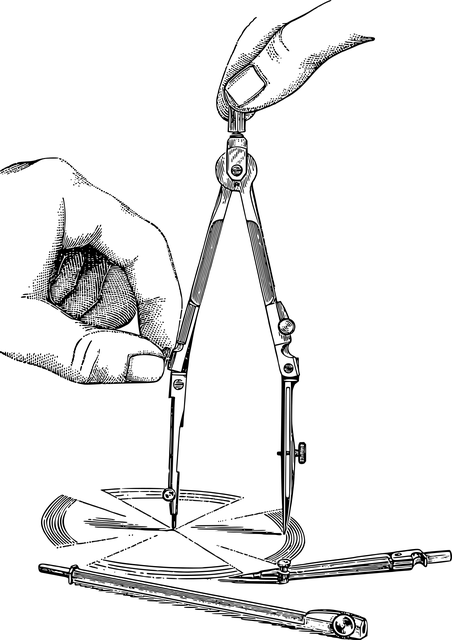

Shop drawings, a critical component in fabrication and manufacturing processes, play a pivotal role in ensuring accuracy and quality. Among various types, steel structure drafting stands out as an indispensable skill. It involves creating detailed technical illustrations that precisely define how individual components of a steel structure should be cut, formed, and assembled. This meticulous process is vital for several reasons.

Firstly, it allows fabricators to visualize the final product before any material is cut or welded, reducing errors and costly rework. Accurate steel structure drafting enables efficient workflow planning, as shop floor workers can anticipate the sequence of operations and necessary tools in advance. Moreover, these drawings serve as a standardized reference point, facilitating communication between designers, manufacturers, and installers, ensuring everyone works from the same set of precise specifications.

Accurate Shop Drawings: The Foundation

Accurate shop drawings are the foundation for successful fabrication and manufacturing processes, especially in the realm of steel structure drafting. These detailed drawings serve as a blueprint, translating abstract design concepts into tangible, measurable specifications that guide the physical creation of structures. Each line, dimension, and note holds significance, ensuring every component is crafted to the exact specifications required.

Shop drawings facilitate clear communication between designers, fabricators, and manufacturers, minimizing errors and misinterpretations. In steel structure drafting, where precision is paramount, these drawings become even more critical. They allow for meticulous planning of cuts, welds, and assembly sequences, ensuring structural integrity and compliance with safety standards throughout the fabrication process.

Manufacturing Process Integration

Shop drawings play a pivotal role in ensuring precision throughout the manufacturing process, especially when integrated seamlessly with the production workflow. In the context of steel structure drafting, this integration is key to achieving accuracy and efficiency. The process begins with detailed technical drawings that translate design concepts into tangible structures. These drawings specify dimensions, materials, and critical tolerances, serving as a roadmap for fabricators.

By aligning shop drawings with manufacturing techniques, such as laser cutting or robotic welding, production teams can automate tasks where possible and maintain consistent quality. This integration allows for real-time data exchange, minimizing errors and rework. In essence, it streamlines operations, making the transition from design to final product smoother and more cost-effective, particularly in high-volume steel manufacturing scenarios.

Quality Assurance Through Drafting Techniques

Quality Assurance Through Steel Structure Drafting Techniques plays a pivotal role in fabrication and manufacturing processes, ensuring accuracy and precision across every stage. Skilled draftspersons meticulously translate design intentions into detailed drawings, serving as a critical control point for quality assurance. By utilizing advanced software and industry-standard practices, they create steel structure drawings that communicate complex spatial relationships, material specifications, and dimensional tolerances with meticulous clarity.

These drawings act as blueprints for fabricators and manufacturers, enabling them to cut, weld, assemble, and erect structures with unparalleled accuracy. Thorough inspection of shop drawings facilitates early detection of potential issues, allowing for prompt corrective actions before the errors escalate on the shop floor. This proactive quality control not only minimizes waste but also ensures the final product aligns seamlessly with design intent, enhancing overall project success.

Shop drawings, particularly those involving intricate steel structure drafting, play a pivotal role in ensuring fabrication and manufacturing accuracy. By integrating these detailed blueprints into the production process, manufacturers can achieve superior quality and precision. Through advanced drafting techniques, industry professionals maintain control over every step, from design to final assembly, fostering an environment of excellence and consistency in steel construction projects. This comprehensive approach to steel structure drafting is paramount for successful project outcomes.